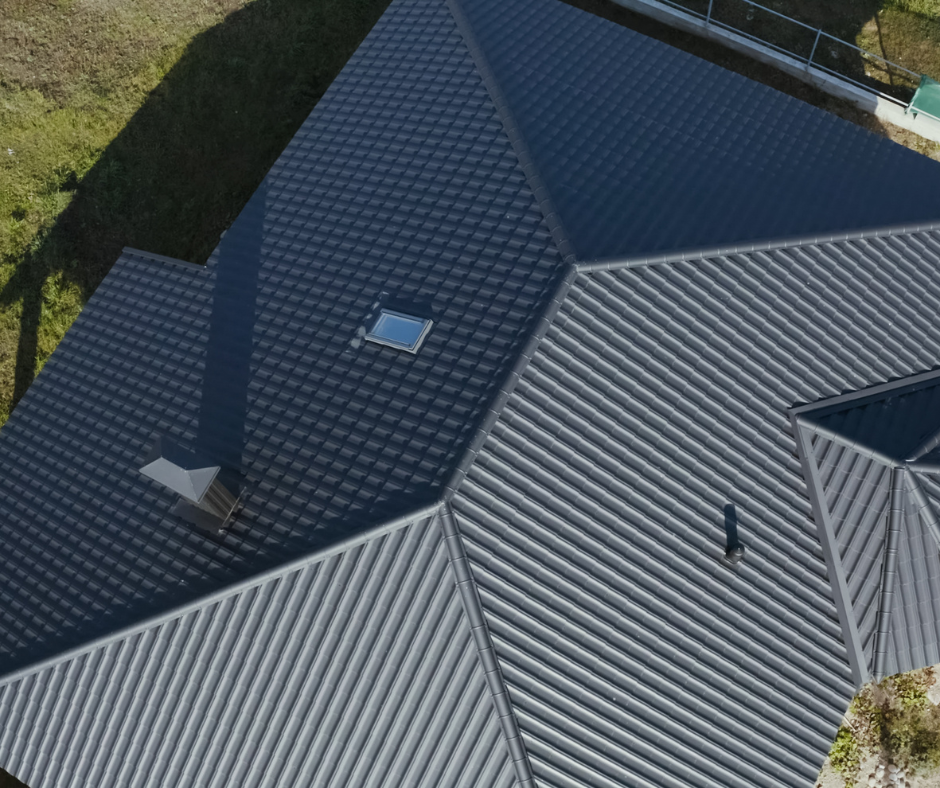

Metal roofs are built to last, but in North Texas, even the toughest systems eventually show signs of age. Between UV exposure, hail, seasonal rain, and temperature swings, older metal roofs often begin to leak at seams, fasteners, and penetrations. The good news? You don’t always need a full replacement.

A high-quality silicone coating system can restore and protect your metal roof for many years — if it’s installed correctly.

As the owner of Shepherd Metal Roofing, I’ve restored dozens of metal roofs across Dallas–Fort Worth using approved silicone systems. Whether your roof is R-panel, standing seam, or another commercial metal profile, here’s what you need to know before choosing a Roof Coating Contractor DFW.

What Is a Silicone Metal Roof Coating?

A silicone roof coating is a seamless, waterproof membrane applied directly over your metal roof. Unlike traditional paint, silicone is a high-performance elastomeric product engineered to flex, stretch, and withstand long-term UV exposure.

Silicone performs best on:

- Aging R-panel roofs

- Standing seam metal roofs

- Metal roofs with seam leaks

- Metal systems with fastener back-out

- Roofs with minor surface rust

A properly installed silicone coating essentially gives your roof a new protective skin for a fraction of the cost of replacement.

Why Silicone Is Ideal for DFW Metal Roofs

DFW weather is brutal on metal roofing — heat, hail, and humidity wear these systems down over time.

Benefits of silicone coatings in North Texas:

1️⃣ UV Resistance

Silicone doesn’t chalk, crack, or degrade under extreme sun exposure — a huge advantage in Texas.

2️⃣ Waterproofing Power

Silicone stands up extremely well to standing water, making it ideal for low-slope metal roofs.

3️⃣ Flexibility

It moves with the roof during thermal expansion, preventing splits and seam failures.

4️⃣ Cost Savings

Restoration typically costs 30–70% less than full replacement.

5️⃣ Energy Efficiency

White silicone coatings reduce heat absorption and lower cooling costs in the summer.

The result is a long-lasting roofing solution that performs beautifully in DFW’s harsh environment.

According to the Metal Construction Association, coating systems are one of the most effective ways to extend the life of aging metal roofs.

Common Problems Silicone Coatings Solve

Before recommending a silicone coating, we evaluate the roof for issues such as:

- Fastener back-out

- Open or separated seams

- Rusted areas

- Cracked or dried sealant

- Failed flashing

- Minor panel dents

- Small punctures or leaks

A silicone coating won’t fix structural issues — but it’s the perfect solution when the roof is still sound but leaking due to age or weather exposure.

Choosing the Right Silicone Coating System

Not all silicone products are created equal. The coating you choose should depend on:

- Roof pitch

Low-slope roofs benefit from high-solids silicone.

- Roof condition

Heavy rust requires a rust-inhibitive primer.

- UV exposure

White silicone offers maximum reflectivity.

- Desired warranty

10–20 year warranties are available depending on coating thickness.

Popular Brands Shepherd Metal Roofing Uses:

- GacoFlex

- Mule-Hide Silicone

- Tropical Roofing Products (TRP)

- Lucas Coatings

We only use manufacturer-approved, commercial-grade products rated for North Texas climates.

How a Certified Contractor Installs Silicone Coatings

Proper installation is everything. A cheap coating job will fail within a few years, while a certified installation lasts decades.

Here’s the step-by-step process for silicone metal roof coating restoration in DFW:

Full Roof Inspection

We identify leaks, rust areas, fastener issues, and panel movement.

Power Washing / Surface Prep

All dirt, oils, biological growth, and loose paint must be removed for adhesion.

Rust Treatment & Primer

Rust-inhibiting primer is applied where needed.

Fastener Replacement & Tightening

Any loose or worn fasteners are replaced with self-sealing screws.

Seam Reinforcement

We embed poly-mesh or butyl tape into seams and penetrations to strengthen them.

Flashing Repair

All vents, curbs, skylights, and edge flashings get resealed.

Silicone Application

Silicone is applied by roller or spray at the manufacturer-required thickness.

Final Inspection & Warranty

We document the installation and provide warranty paperwork.

How Long Do Silicone Metal Roof Coatings Last?

Depending on coating thickness and application method, silicone coatings typically last:

- 10 years at 20 mils

- 15 years at 25 mils

- 20 years at 30 mils

After that, the system can usually be recoated, giving your roof multiple life cycles.

This makes silicone coating one of the most cost-effective metal roof solutions in DFW.

Why Homeowners & Businesses Trust Shepherd Metal Roofing

Choosing the right contractor is just as important as choosing the right coating.

At Shepherd Metal Roofing, we provide:

- Certified silicone coating installation

- Detailed inspections with photos

- Seam and fastener reinforcement

- High-solids, commercial-grade materials

- Full transparency and honest recommendations

- Long-term warranties

- Clean, efficient job sites

If your metal roof still has life left in it, a silicone restoration may be the best investment you can make.